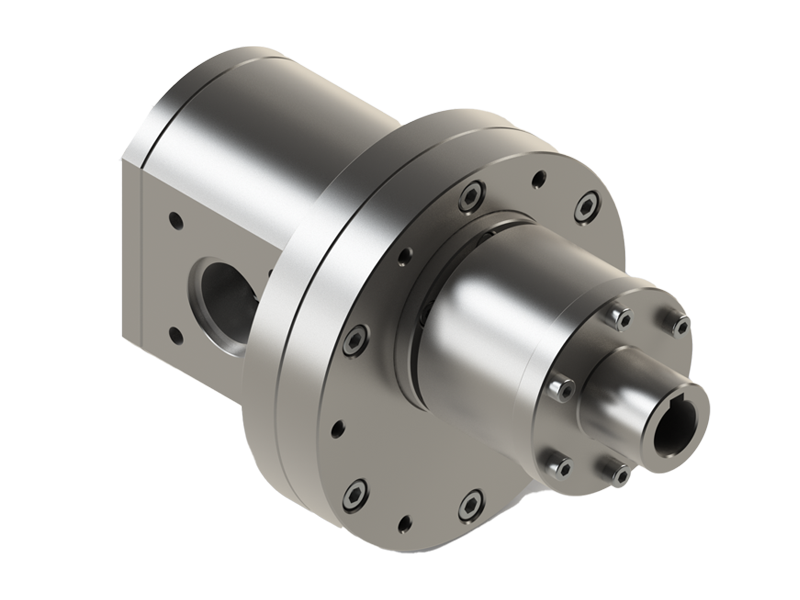

OM-CM 低粘泵

●The gear pump is used to convey and meter materials with medium and low viscosity.

●It is suitable to convey and meter traditional chemicals and pharmaceuticals as well as polymer monomers, oligomers and prepolymers, widely used in chemical, cosmetic, food, petrochemical and polymer industries. OM-CM shaft seal is a synchronous magnetic coupling seal, 100% leak-free. The pump is east to operate and smooth, and the pump speed is always equal to the input speed of the motor. It can also be used to convey toxic and flammable media with high temperature and high pressure.

●Suitable for very low viscosity

●Accurate flow rate

●Precise structure

●Minimal pulsation

●Minimal pulsation, leak-free

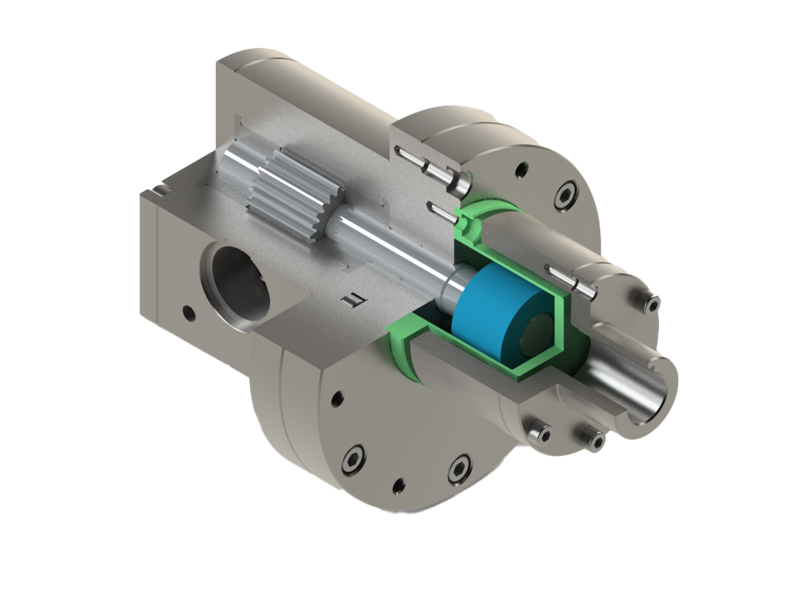

Gear

Heat-resisting stainless steel, duplex stainless steel, duplex titanium, Hastelloy, etc.

Sliding Bearing

Carbon graphite, silver-nickel alloy, silicon carbide, Zirconia, tool steel, copper-aluminum alloy, etc.

Pump Body

Stainless steel, tantalum alloy, titanium alloy, Hastelloy, ceramic

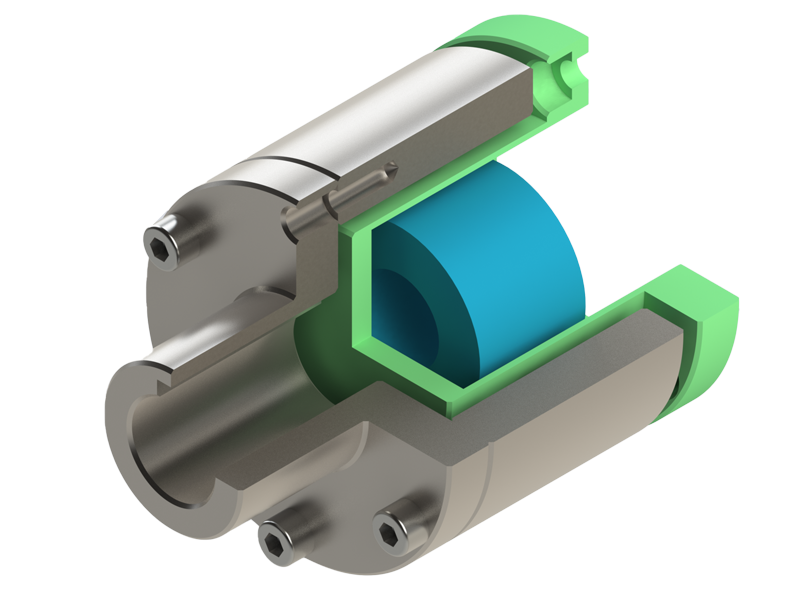

Shaft Seal

Magnetic coupling seal

Organic and inorganic chemicals: ethanol, additives, matrix, esters, glycerin, resin, hardener, isocyanate, monomer, oil, phenol, acid, biodiesel, asphalt, tar, hot melt adhesive, glue, Paraffin, lactic acid, etc.;

Polymer: acetate, nylon, prepolymer, etc.;

Food: vegetable oil, butter, margarine, condiments, chocolate, fudge, glycerin, chewing gum, vitamins, syrup, gum, etc.;

Pharmaceuticals and cosmetics: amino acids, moisturizers, shampoos, vitamins, etc.

| Material viscosity | ≤30Pa.s(≤30000cP) |

| Inlet pressure | Vacuum-20.0MPa(200bar) |

| Work Temperature | ≤150℃(302℉) |

| Differential pressure | ≤12.0MPa(120bar) |

| Heating mode | Electric heating, heat medium heating |

| The above values are the max ones allowed, which may not be reached under certain circumstances | |

| Model | ml/r | Model | ml/r | |

| CM-1 | 1 | CM-700 | 700 | |

| CM-3 | 3 | CM-800 | 800 | |

| CM-5 | 5 | CM-1000 | 1000 | |

| CM-10 | 10 | CM-1200 | 1200 | |

| CM-20 | 20 | CM-1400 | 1400 | |

| CM-30 | 30 | CM-1600 | 1600 | |

| CM-50 | 50 | CM-2000 | 2000 | |

| CM-100 | 100 | CM-2500 | 2500 | |

| CM-150 | 150 | CM-3200 | 3200 | |

| CM-200 | 200 | CM-4300 | 4300 | |

| CM-300 | 300 | CM-6300 | 6300 | |

| CM-400 | 400 | CM-8000 | 8000 | |

| CM-500 | 500 | CM-9000 | 9000 | |

| CM-600 | 600 | CM-12000 | 12000 |

(For other specifications, please contact the supplier for details, special customization is available)