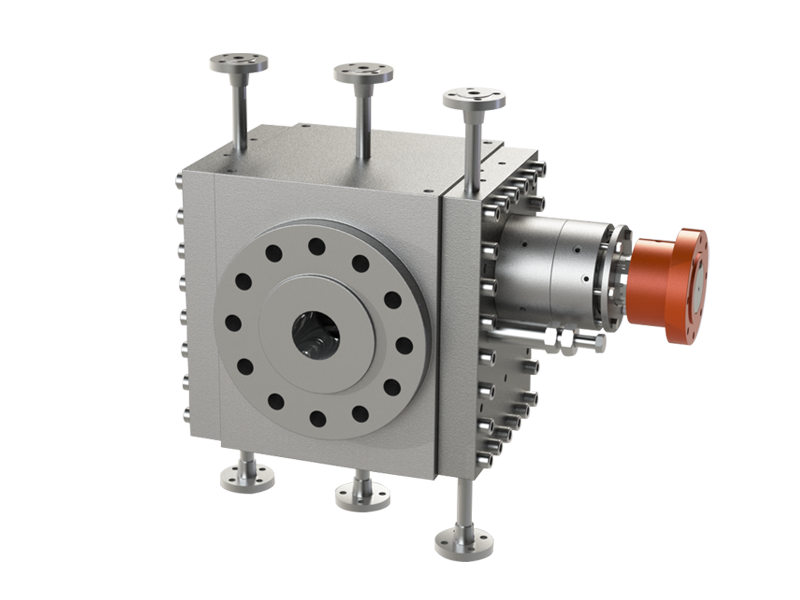

OM-E系列管道增压输送泵

●OM-E gear pump is used to convey and pressurize medium and high viscosity media in the process industry.

●It adopts liquid phase (such as thermal oil) or vapor phase (such as steam) jacket heating, convey prepolymers and polymers such as PET, PBT, PA, PC, PS, SAN, ABS, HIPS, PP, PE, POM, EVA, PLA, PEEK and other media.

●High reliability

●Efficient conveying

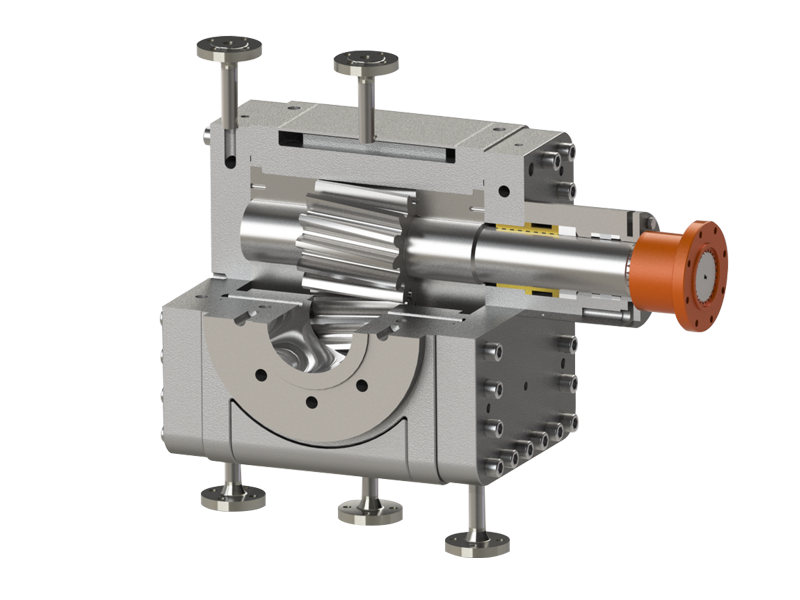

Gear

Stainless steel, tool steel, Hastelloy, nitrided steel, specialty steel and coated gears.

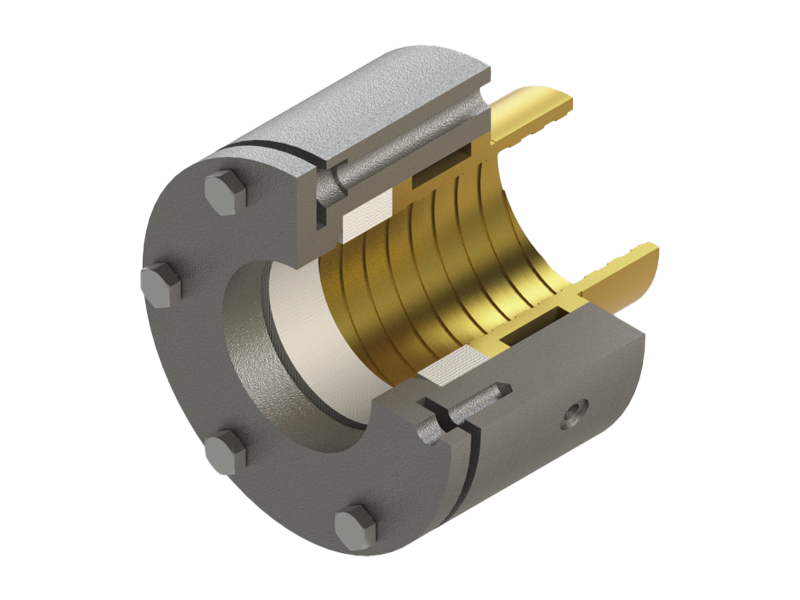

Sliding Bearing

Tool steels, silver-nickel alloys, copper-aluminum alloys, specialty materials and coated bearings

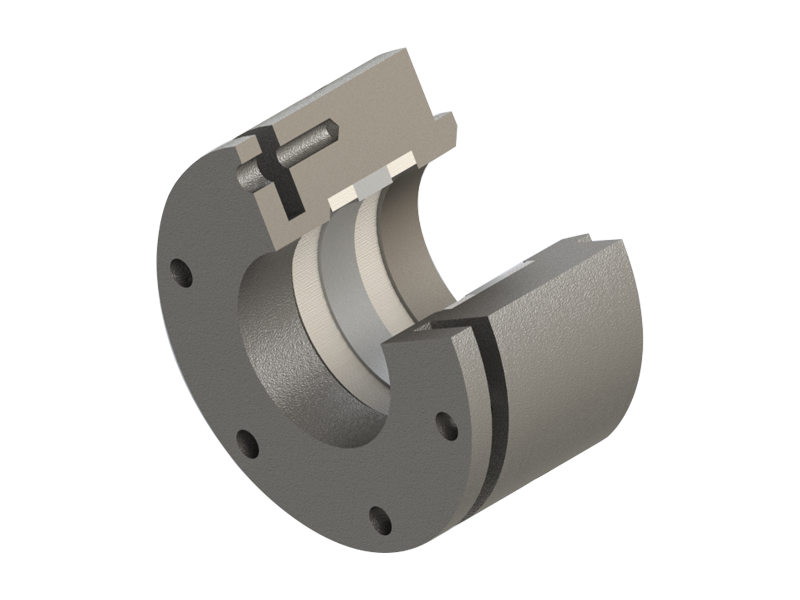

Pump Body

Heat-resisting steel, carbon steel, nitrided steel, Hastelloy, stainless steel, and coated pump body

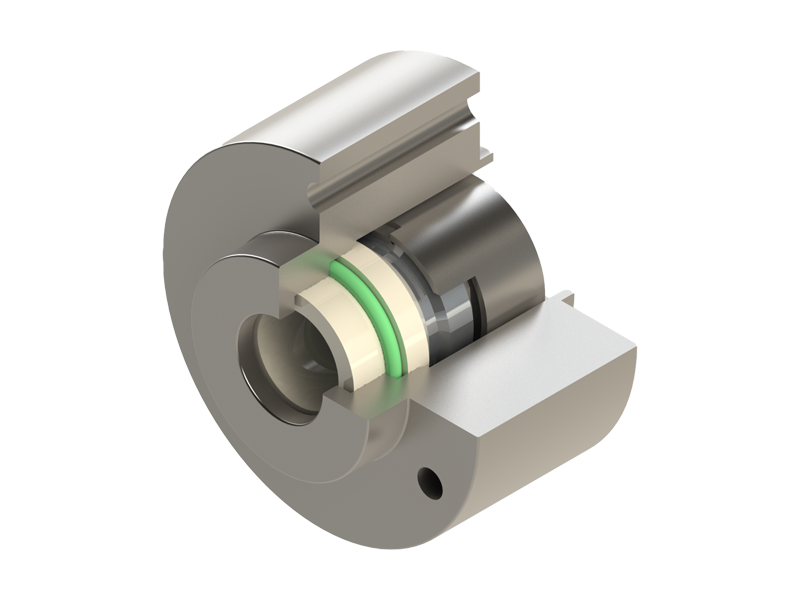

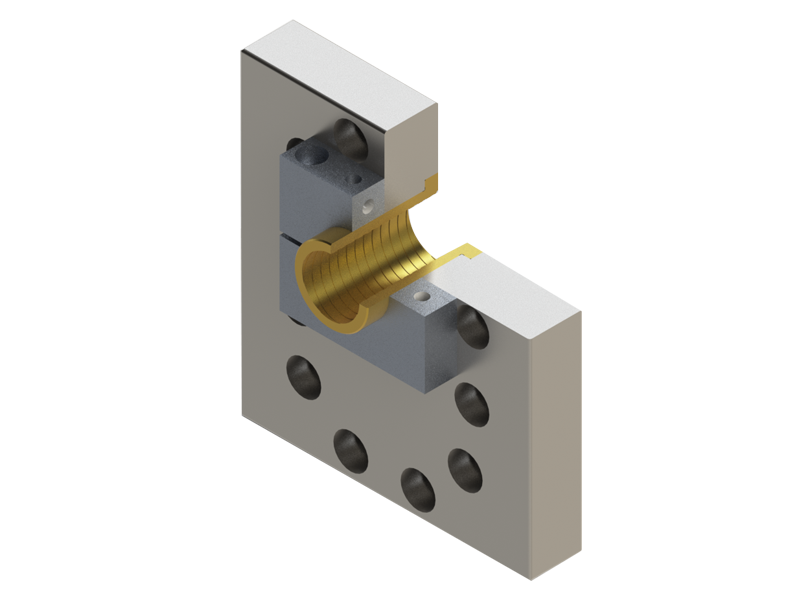

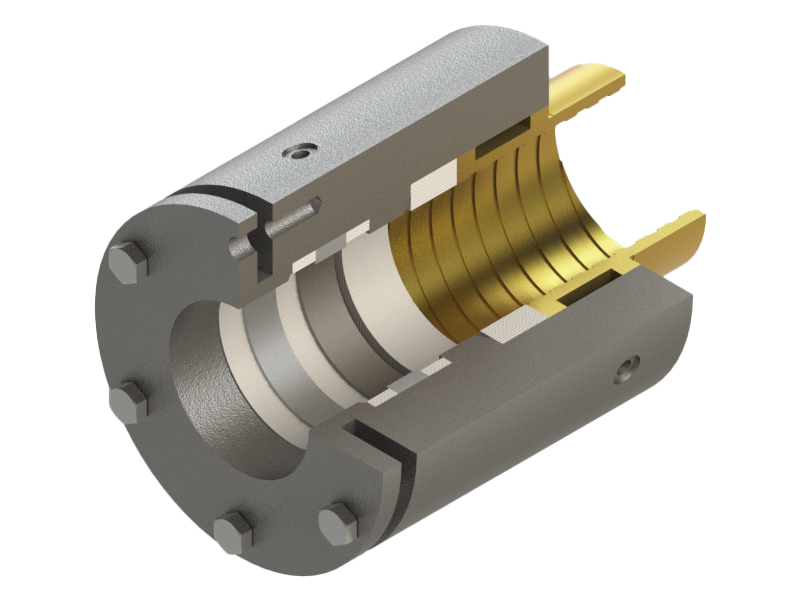

Shaft Seal

Spiral seal, vacuum spiral seal, packing seal, spiral seal and packing box seal as combined bearings

PET, PBT, PTT, PA, PC, PS, PB, SAN, ABS, HIPS, PP, PE, POM, EVA, PLA, PEEK, TPU, TPE, PMMA and raw liquor, solutions, oligomers, and prepolymers in the industry of other high polymer materials.

| Material Viscosity | ≤ 40,000Pa.s(≤40,000,000cP) |

| Work Temperature | ≤ 350℃(662°F) |

| Heating Mode | Liquid phase (thermal oil) or gas phase (steam) electric heating |

| OM-EL Low Pressure Booster Pump | Inlet Pressure |

≤ 5.0MPa(50bar) |

OM-EH Heigh Pressure Booster pump | Inlet Pressure |

≤ 12.0MPa(120bar) |

| Differencential Pressure |

≤ 5.0MPa(50bar) |

Differencential Pressure |

≤ 25.0MPa(250bar) |

||

| The above values are the max ones allowed, which may not be reached under certain circumstances | |||||

| Model | ml/r | Model | ml/r | |

| E-5 | 5 | E-1200 | 1200 | |

| E-10 | 10 | E-1400 | 1400 | |

| E-20 | 20 | E-1600 | 1600 | |

| E-30 | 30 | E-2000 | 2000 | |

| E-50 | 50 | E-2500 | 2500 | |

| E-100 | 100 | E-3200 | 3200 | |

| E-150 | 150 | E-4300 | 4300 | |

| E-200 | 200 | E-6300 | 6300 | |

| E-300 | 300 | E-8000 | 8000 | |

| E-400 | 400 | E-9000 | 9000 | |

| E-500 | 500 | E-12000 | 12000 | |

| E-600 | 600 | E-18000 | 18000 | |

| E-700 | 700 | E-25000 | 25000 | |

| E-800 | 800 | E-38000 | 38000 | |

| E-1000 | 1000 | E-54000 | 54000 |

(For other specifications, please contact the supplier for details, special customization is available)